Produkter

Astro systems are built on RNA technology and combine advanced 3D design and simulation […]

Hoppers are often an overlooked but essential component of vibratory systems. They function by […]

RNA components are aimed at those who want to create their own solutions. As […]

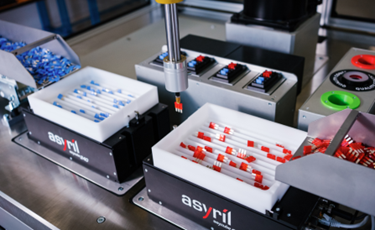

Flexible conveying systems from Asycube, using 3-axis vibrations, enable extremely gentle separation of workpieces. […]

Traditional vibratory systems still account for the largest share of the automation conveying systems […]

Promess supplies control cabinets, various BUS communications, press stands and much more.

Promess offers a comprehensive range of torque testers designed to test the torque in, […]

An electric press system from Promess is a central component of a quality system. […]

Zimmer Group is the world’s largest supplier of clamping elements and the inventor of […]

Zimmer shock absorbers typically win all tests. They are designed around the patented “snail […]