Produkter

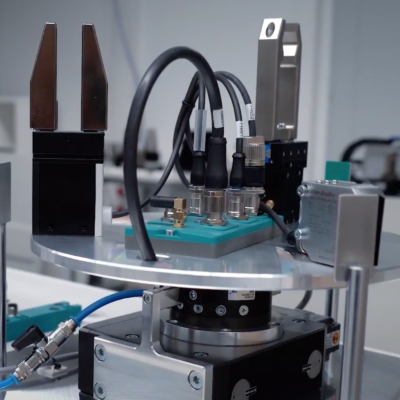

The most important accessories for tool changers are energy elements, which enable the transfer […]

We offer a comprehensive range of angles and adapter plates that add value to […]

The use of tool changers enables rapid change of “hands” on the robot, making […]

Special grippers are standard at Zimmer. The company has a dedicated department that works […]

Zimmer was among the first to launch a full line of collaborative grippers for […]

Manual systems from Stöger Automation are complete solutions that only require air and power […]

Stöger Automation has many years of experience with automatic systems that offer full monitoring […]