High precision for tasks that require low effort and maximum accuracy!

The UFM Precision5 is an advanced precision press created for assembly and joining tasks with a focus on superior precision. The press is ideal for lower-load applications where accuracy is of the utmost importance. The series is particularly popular in the medical and electronics industries.

Flexible configurations:

The UFM Precision5 offers versatile customization options so you can get exactly the solution that suits your needs. You can choose between different configurations, depending on whether you need a brake or not, and whether you prefer piezo or strain gauge force transducer.

User-friendly design:

UFM Precision5 is designed with ease of use in mind. It ensures precise, effortless joints and can be customized to your specific requirements. With a solid construction, it is built to last and ensure stable performance over time.

Make your assembly process more precise and efficient with UFM Precision5.

Specifications

- AC servo motor with absolute encoder (except 200 N unit)

- Drives

- Steel cabinet

- Non-rotating press plunger with precision guidance

- Piezo or strain gauge force transducer

- Tool holder

Intelligent control for easy operation

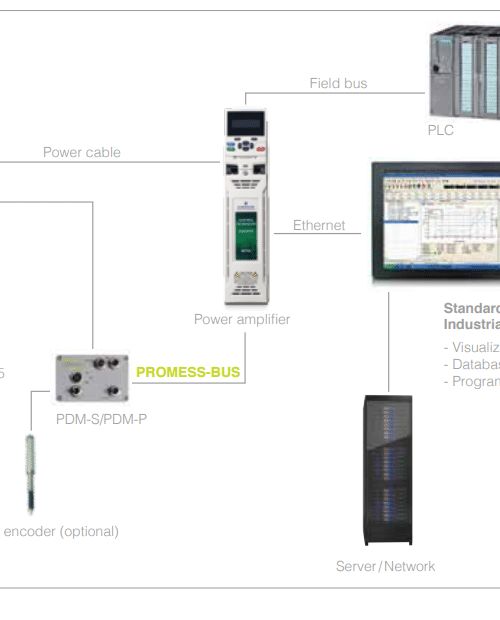

The UFM Precision5 is controlled by a power amplifier with an integrated NC module. A built-in RISC processor coordinates the assembly press and can be easily programmed and operated using a standard PC with a monitor.

The controller handles both the mechanical movement of the press and the monitoring of force and distance. The force-distance progression can be monitored using simple methods such as envelopes and/or windows. Data can be edited numerically and graphically, making it easy to follow each process.

The automatic learning feature allows you to avoid the use of specialized programming and instead simply learn the processing limits with the help of a well-executed part.

Quality assurance data is stored using the database plugin and can be reused at any time.