Produkter

Stöger Automation is a specialist in delivering complete systems that include feeding. The system […]

Special solutions are standard at Weiss. The company has a dedicated department that works […]

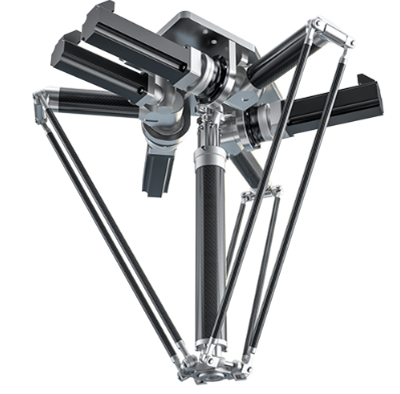

Delta robots are lightning fast, lightweight and accurate, designed specifically for high-speed assembly with […]

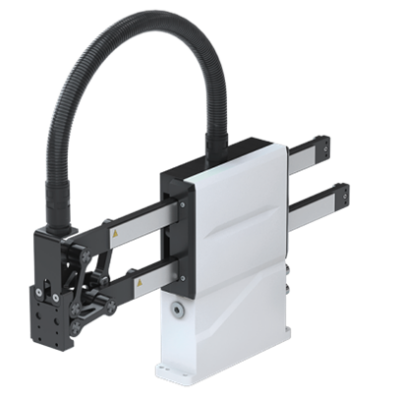

HP units are lightning-fast and complete pick-and-place solutions powered by linear motors. They offer […]

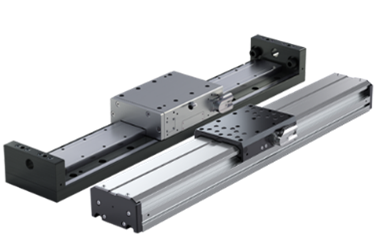

The HG/HN/HL modules are available in lengths up to 10 meters and can handle […]

Weiss delivers complete machines, allowing you to concentrate on your core business. Let us […]