ASTRO feeding systems from

United Components

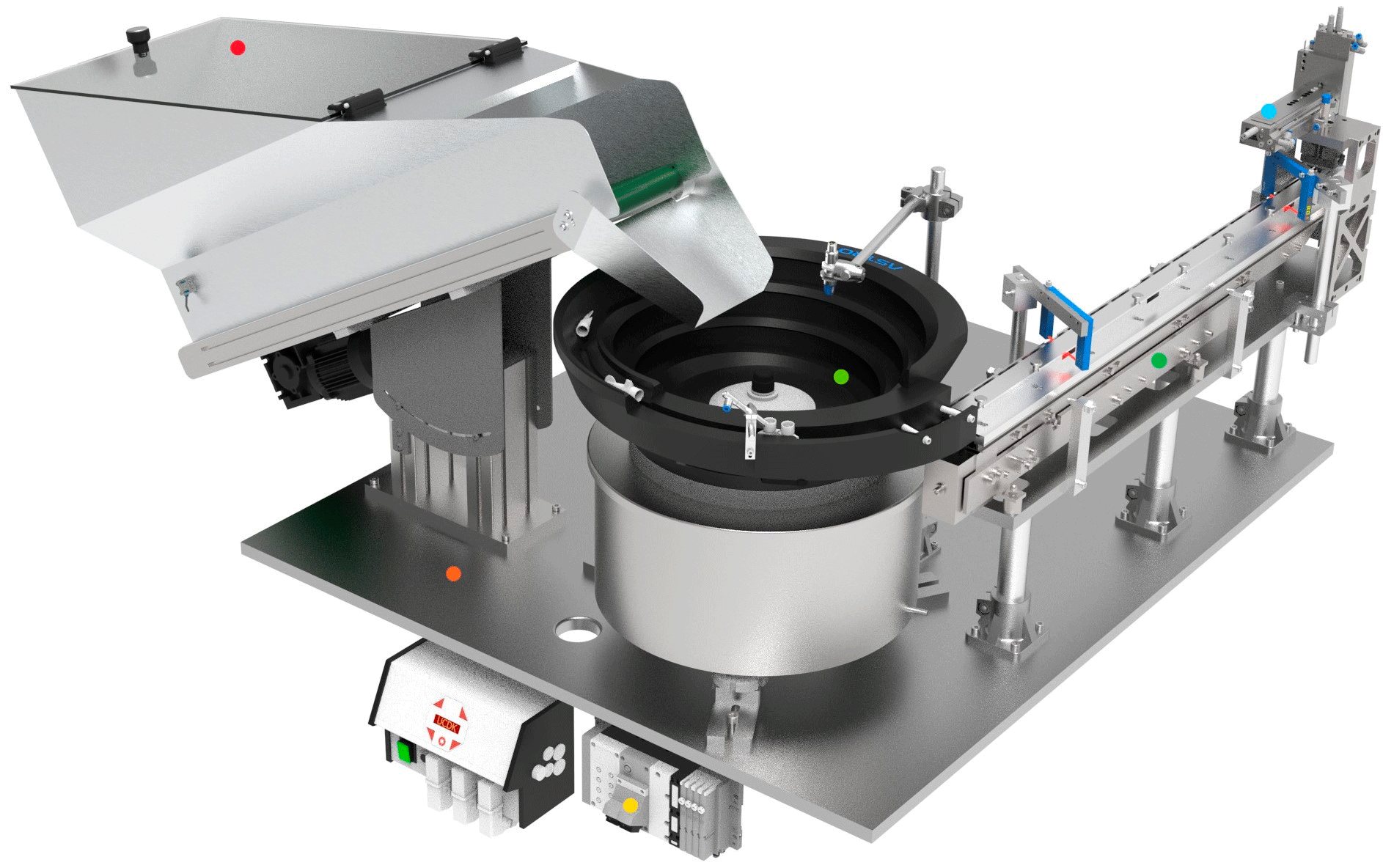

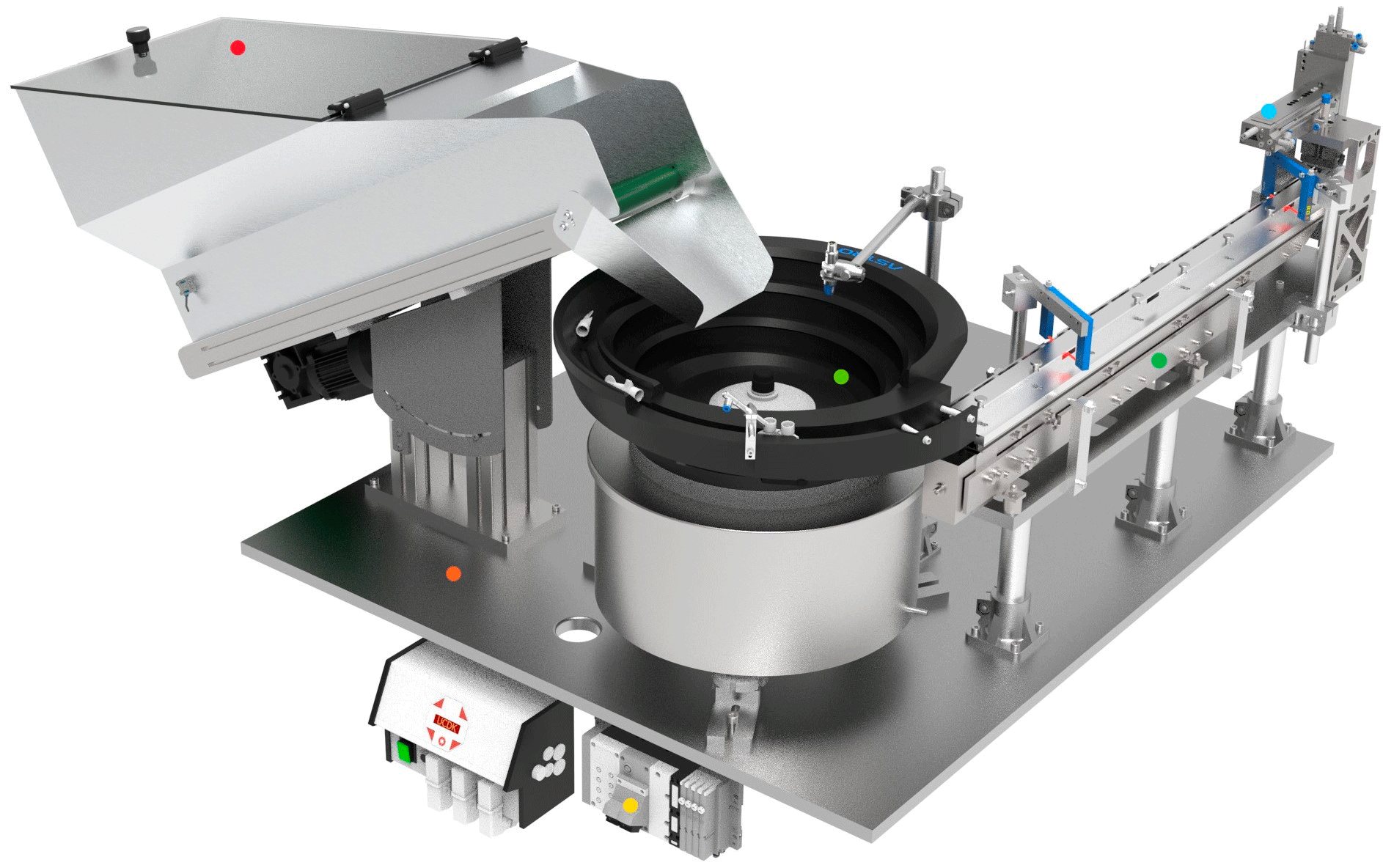

ASTRO feeding systems

Astro feeding solutions was founded in 2020 by passionate specialists who have more than 25 years of experience and know-how in feeding all kinds of parts; from simple washers, to complex parts for use in the pharmaceutical industry.

We focus on the optimal solution for each task!

Some parts are best feeded in a traditional vibrator system, others parts are best suited for a stair feeder, etc. At Astro we focus on the optimal solution for your task. Astro is 100% designed in 3D CAD and the solutions themselves are manufactured using a 5-axis machining centre. The advantages of this are obvious:

* Bunker solutions:

- Vibrating bunkers

- conveyor bunkers

- Giraffes

- From 0.3 to 1,000 litres

* Vibrator in polyamide:

- Designed in 3D CAD

- Manufactured in 5-axis machining centre

- 99% reproducibility

- Possibility of surface treatment

* Single trap / dead land:

- Removal of parts

- With pneumatic or electric modules

* Fully documented:

- Documented according to 2006/42/EC, paragraph 13

- Complete parts lists

* Management of the system:

- Controls for integration with HMI

- Management of the whole system

- With Ventilø and BUS communication

* Linear rails:

- Linear vibrator up to 3.000 mm.

- conveyor up to 5.000 mm.

Innovation in feeding technology

Design:

- Dummy layout already on request

- 100% reproducibility in solution, providing economic benefits for rebuilds

- Detailed documentation and traceability in solution

- Unique level of detail of system before manufacturing the finished solution

Production:

- Machined in 5-axis machining centre, allowing tolerances down to 1/10 mm.

- Manufacturing allows system to be rebuilt with 99% reproducibility

- Low noise material with unique wear properties

- Accurate fit to part geometry

Technology:

- Vibrator tops up to Ø650 mm in black/white Polyamide. Available in FDA approved material

- Linear rails up to 3.000 mm.

- Vibrator control, operation via HMI or complete control box, controlling the system

- Vibrator drive that gives minimum vibrations down to the floor, and does not interfere with other vibratory drives on the same plate

Complete documentation

- Systems that are 100% documented according to 2006/42/EC, paragraph 13 concerning partly completed machinery

- Parts lists, spare parts lists and, where applicable, pneumatic and functional diagrams

- Complete parts lists

Do you need guidance?

Then contact us today for a no-obligation chat about how we can make a difference for you.

UNITED COMPONENTS A/S

Korsholm Alle 21

5500 Middelfart

Denmark

Tel: +45 64 40 09 70

CVR: 27154948