The 4th industrial revolution / Industry 4.0

News

2 April 2020

The 4th industrial revolution / Industry 4.0

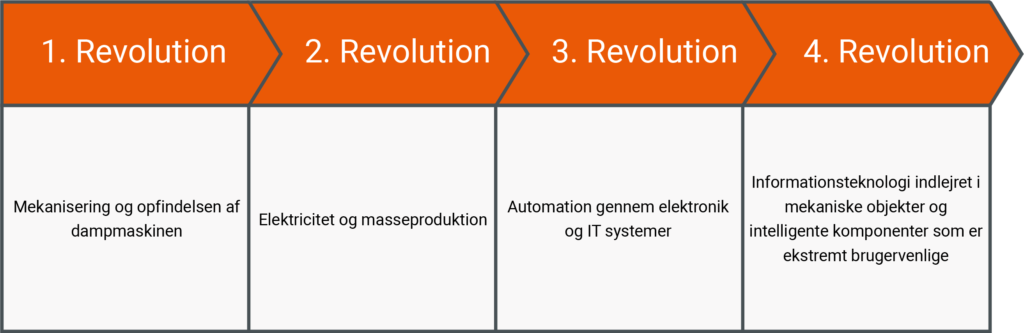

If you have an interest in manufacturing and automation, you've certainly encountered the term 4.0.

The term Industry 4.0, is the vision of German researchers for the next innovation step in manufacturing, based on the "smart factory" of the future.

It is important to keep in mind that the whole idea of Industry 4.0 is built around a vision for the future, and there are therefore wide limits to what can be considered as being within this vision or outside it. The ideas behind the 4th Industrial Revolution include:

Information technology embedded in mechanical objects (Embedded systems).

The interaction between the physical objects and the associated knowledge (Cyber-Physical Systems - CPS) is a further development of Embedded systems. These are self-learning objects that use their knowledge and information to tell the production system how to handle them.

Products and machines etc. exchanging services and information in real time, where e.g. Track-and-trace via Radio Frequency Identification (RFID) is seen as one of the technological prerequisites for e.g. Cyber-Physical Systems, as described earlier.

Faster development and integration with production, using Product Lifecycle Management (PLM), where virtual prototypes and simulations enable lightning-fast development.

Integrated solutions, (Life Cycle Engineering), where mechanical design, electrical design and the automation solution are integrated into a single software-based concept, thus accelerating commissioning and start-up quickly and flexibly.

United Components

At United Components we supply high-end components for automation, and therefore have a special focus on the part of 4.0 that has to do with automation of assembly.

These are typically components that contain intelligence and are simple to use and install, often with M12 connectors where both power and signals are in the same connector and which are quickly and easily implemented in the overall control system (PLC, Industrial PC etc.).

Unlike traditional products, 4.0 products often have a simple and innovative programming, or "teach" function, which makes the component simple to use and program, with the ability to store and recall the various programs and parameters within the component, providing extended diagnostic and maintenance capabilities.

Thus, the products are directly involved in quality assurance of production through simple diagnostic options, and enable analog communication without loss of up to 20 meters, between the component and the overall system, as well as offering data storage.

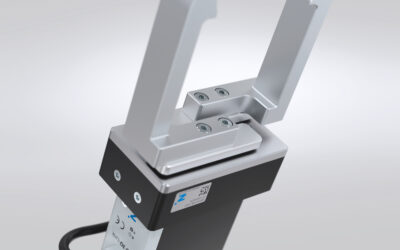

A good example of 4.0 is the new gripper series from Zimmer group.

Read our latest news

We welcome Lasse to our engineering department

We welcome Lasse to our design departmentLasse has started as a Design EngineerThe demand for our customized ASTRO feeding systems continues to increase, and therefore we have...

Did you say part?

Did you lose your part?News With the GEP2000 series from Zimmer Group , your part is always in safe hands! The GEP2000 series from Zimmer is equipped with a self-locking mechanism that automatically secures and...

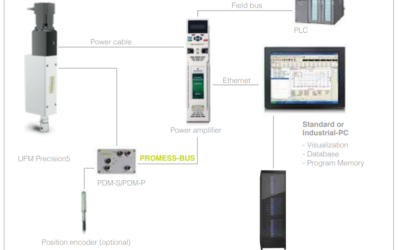

UFM Precision5

UFM Precision5 from PROMESSNewsHigh precision for jobs that require low effort and maximum accuracy!The UFM Precision5 is an advanced precision press designed for assembly and joining jobs with low effort and...

UNITED COMPONENTS A/S

Korsholm Alle 21

5500 Middelfart

Denmark

Tel: +45 64 40 09 70

CVR: 27154948